Welcome to your premier hub for reliability engineering

Place where years of shared experience converge to tackle the toughest questions in design of experiments (DOE), RxxCxx planning(R90C90 reliability and confidence levels), accelerated life testing (ALT), sample size, wear and aging models, run-to-failure strategies, damage estimation, life reliability projections, and optimal test-duration decisions.

Cutting product failures through accelerated life testing (ALT) pays off across every sector: fewer field breakdowns slash warranty costs and recall risk, optimized maintenance plans keep assets productive instead of idle, and early‐stage stress testing surfaces design flaws months sooner, shrinking development cycles and speeding time-to-market. By front-loading reliability validation, companies avoid the multimillion-dollar hits, reputational damage, and engineering fire-drills that automotive, electronics, medical, and energy firms routinely suffer when recalls force them to scramble for fixes under public scrutiny.”

Tools Highlights

Tool to calculate sample size as function of test duration, Tool to create RxxCxx line based on the ALT run to failure test results, AF accelerated factor estimate

Sample Size vs. Test Duration Calculator

This tool estimates the required number of test samples as a function of planned test duration, ensuring statistical confidence in reliability outcomes. It helps balance test scope, resource constraints, and confidence levels.

RxxCxx Line Generator

Based on ALT run-to-failure data, this tool creates reliability (R) vs. confidence (C) trade-off lines. It enables engineers to visualize achievable reliability levels at given confidence intervals from experimental results.

Acceleration Factor (AF) Estimator

This tool calculates the acceleration factor between test conditions and use conditions. It supports mapping accelerated life test results to real world field performance, improving predictive accuracy.

Read My Latest Articles

Insights, strategies, and stories from my work in product, growth, and technology.

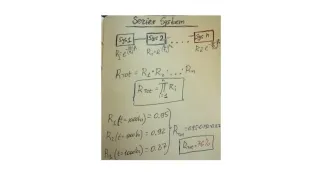

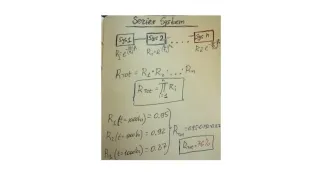

Series-Connected Subsystems

Complex electromechanical products rarely rely on a single mechanism; they knit together motors, sensors, power electronics, and software into an interdependent whole. When these blocks are wired in s... ...more

DOE

September 05, 2025•2 min read

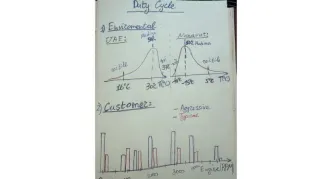

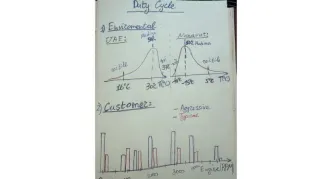

Duty Cycle Engineering

A clearly defined duty cycle—the time-weighted map of every load, rest period and environmental exposure a product sees—anchors both design and testing. When engineers know how long a motor will dwell... ...more

DOE

September 05, 2025•3 min read

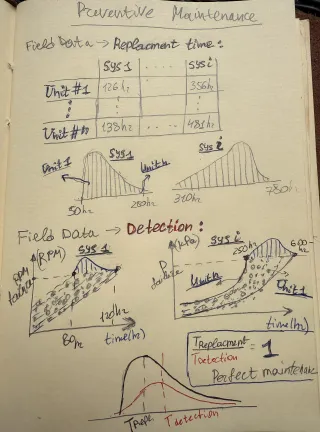

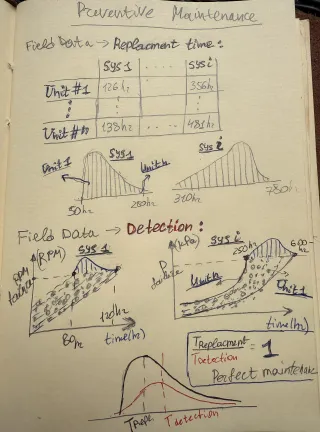

Preventive maintenance: Replacement vs. Detection

Two mindsets dominate preventive maintenance. Time-based replacement swaps parts after a fixed number of hours, cycles, or calendar days; its simplicity and regulatory compliance keep it the workhorse... ...more

Friction ,DOE &Data

September 05, 2025•2 min read

Data-Driven Detection of Accelerated Wear in Critical System Components.

Data-Driven Detection of Accelerated Wear in Critical System Components. ...more

Data

January 24, 2025•2 min read

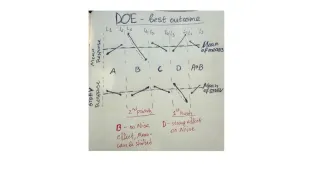

DOE: Variability First, Mean Second

Career transitions can be exciting yet challenging times, whether you’re switching industries, pursuing a promotion, or starting your own business. The process often comes with uncertainty, self-doubt... ...more

DOE

January 24, 2025•3 min read

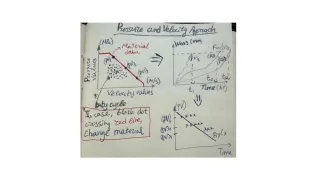

Friction Testing: PV Approach

Self-discovery is a journey that allows you to understand your true self—your strengths, values, passions, and purpose. It’s the foundation for personal growth, confidence, and fulfillment. Life coach... ...more

Friction

January 24, 2025•2 min read

Stay Updated with My Weekly Insights

Each week, I publish fresh perspectives, strategies, and case studies on reliability engineering—from accelerated life testing to design validation and beyond.

Explore in-depth articles covering:

Cutting-edge reliability methodologies

Real-world case studies from multiple industries

Practical tools & resources for engineers and leaders

Expertise

With deep expertise in reliability engineering across the entire product development lifecycle, I specialize in accelerating design validation and ensuring robust field performance. My approach integrates advanced reliability strategies from the earliest development stages—leveraging tools like DFMEA, boundary diagrams, and P-diagrams to systematically identify and mitigate potential failure modes in subcomponents. This proactive, structured methodology not only streamlines the path to market but also improves product reliability and customer satisfaction.

Recognizing that thorough documentation and effective use of "paperwork" tools bring tremendous value to organizations of any size, I drive processes that make reliability visible and actionable at every decision point. My ability to translate technical reliability insights into practical, business-focused benefits enables teams to minimize risk, contain costs, and build a solid foundation for long-term product success.

Read Our Latest Blogs

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Series-Connected Subsystems

Complex electromechanical products rarely rely on a single mechanism; they knit together motors, sensors, power electronics, and software into an interdependent whole. When these blocks are wired in s... ...more

DOE

September 05, 2025•2 min read

Duty Cycle Engineering

A clearly defined duty cycle—the time-weighted map of every load, rest period and environmental exposure a product sees—anchors both design and testing. When engineers know how long a motor will dwell... ...more

DOE

September 05, 2025•3 min read

Preventive maintenance: Replacement vs. Detection

Two mindsets dominate preventive maintenance. Time-based replacement swaps parts after a fixed number of hours, cycles, or calendar days; its simplicity and regulatory compliance keep it the workhorse... ...more

Friction ,DOE &Data

September 05, 2025•2 min read

© 2025- All Rights Reserved.